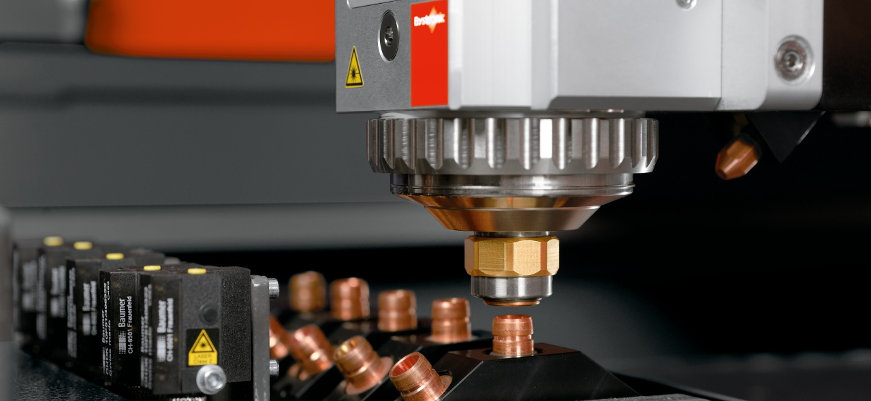

Laser Cutting Head And Optics Are The Key To Laser Cutting Success

The innovations and the technological development of laser optics or laser cutter heads have greatly contributed to the development and the improvement of the laser cutting quality. Operator interventions in the laser cutting process are becoming less necessary, and the emphasis is placed on the complete cutting automatization, which can be achieved through the latest innovations in this technology.

Technological advancement of laser cutting

The development of the laser cutting technology brings the ability to cut all the slim materials. In addition, the advancement of the laser cutter components increases the precision as well as the possibility of performing more complicated cuts.

However, laser cutting had a completely different application in the past. This applies primarily to the most used CO2 lasers. Laser technology has provided almost an ideal way to produce prototype tools and various other components that required the manufacture of larger sized mechanical cutters.

Optics as key to success

By the increase of the demand when it comes to quality and cutting in general, a need for innovation development that would make the laser optics more efficient appeared. At the very beginning, laser cutters used one lens with only one focal length, which greatly restricted laser cutting.

However, after the appearance of multi-lens laser technology, laser cutting took place at higher speeds and its quality has increased as well. Although initially, the lens replacement was a complicated process in which the cutter head needed to be dismantled and it lasted for a relatively long time, many companies decided to install additional lenses into their laser cutter.

The need for better laser optics resulted in the development of the autofocusing system. With this system, the operator no longer had to manually adjust the focus of the lens, but the focusing system would do it automatically. This increased the speed and the quality of the cut with minimal waste of time. In addition, by developing and enhancing the laser cutter head, lens replacement has become simpler and today it lasts for an average of 20 minutes.

Laser cutting automatization

The development of automatization has caused the increase in cutting speed. The CNC technology has been further upgraded so the laser cutter could run many more complex positions without any problems. Additionally, the automatic cutting of metal plates on the laser cutter’s work desk accelerated the entire cutting process, and the operator could focus exclusively on laser cutting parameters.

Apart from the automatization of the modification of the metal plate being cut, automatic changes of the cutting head were done as well. Due to the need for the change of the laser lens during cutting, a system is designed to automatically adjust the lens, or physically replace the head of the laser cutter. With this kind of system, the laser cutting process is further accelerated and becomes more efficient.

The evolution with the appearance of the fiber laser

With the emergence of a new type of laser technology, fiber laser, which has enabled the creation of laser beams of greater intensity or strength, previous CO2 lasers have been replaced by considerably better fiber lasers, which for creating laser beams use a special type of diode instead of gas.

Fiber lasers have also led to increased cutting efficiency. CO2 cutters invest only 10% of the energy they use into the cutting process, whereas with fiber lasers, this figure increases to as much as 35%. Nonetheless, CO2 is still being used because of its advantages in laser metal cutting.

What does the future bring?

Today, laser technology is at a turning point. Will the industry see the benefits of fiber laser or will it continue to use CO2 lasers? Numerous engineers trying to answer this question are pointing to new innovations in the field of laser optics or laser cutter heads.

he latest innovations bring the diminution of any need for major operator interventions in the laser cutting process. In the future, it is to be expected that laser cutting will remain the primate, ie synonym for quality and the best price and quality ratio when it comes to cutting both metal and other materials.